Editorial Posted by Naava on November 2, 2017

Naava's Journey Through the Factory

What does it take to combine nature’s innovation with high tech?

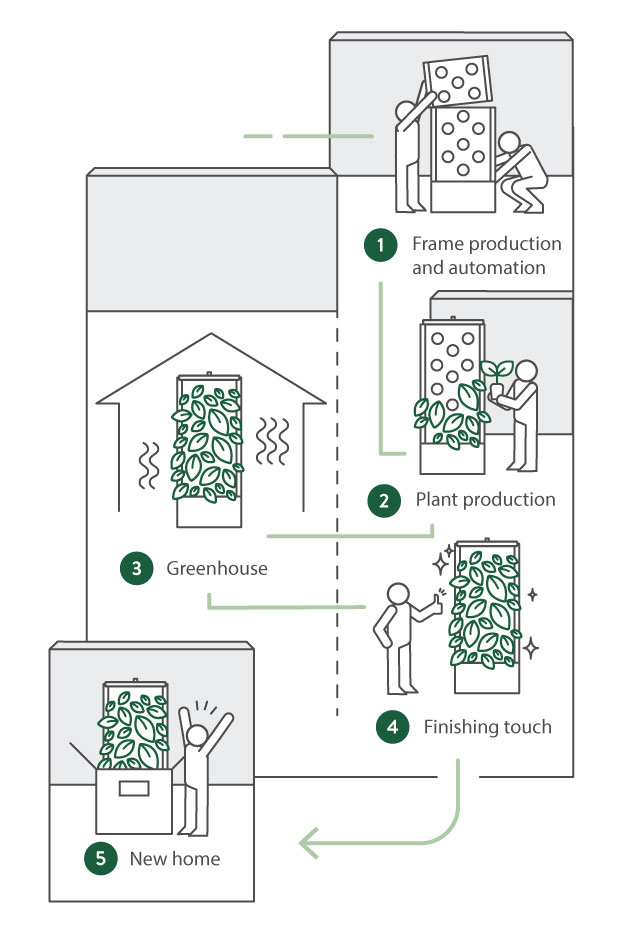

At Naava Factory, the smart green wall makes its way through various different workstations where it’s assembled into a unique entity. The capable hands of Naava’s production team work together to combine individual parts into the world’s smartest green wall.

Unique technology hidden inside the frame

The actual journey of the smart green wall begins in the frame production. In the vast production hall, individual materials are worked into modules and an automated system that works as the basis of Naava, making a simple green wall a smart green wall.

In order to make sure that every smart green wall is unique, functional and top quality, every step of the manufacturing process is done by hand. Naava’s frame starts to take its shape once the metal and frame parts are pressed into modules on the production table, which has been developed for the production of modules.

Naava’s sub-assembly is also manufactured in frame production. The sub-assembly forms the automated system of the smart green wall. It includes an electronic panel, sensor technology, fans circulating indoor air, and the remote monitoring system. Together the various parts of the automated system guide and monitor Naava’s functions.

The individual parts of Naava create an all-inclusive entity that takes care of itself.

In addition, it is here that Naava receives water pipes for its automated irrigation system as well as a light fixture which takes care of lighting of the plants, even in darker conditions. The irrigation and lighting together with the sub-assembly make sure that the plants have stable living conditions.

Artificial intelligence guarantees self-sufficiency

The functionality and self-sufficiency of Naava’s automation are ensured with air circulation, irrigation system, lighting and various different components. However, the systems and components themselves can’t tell Naava what to do in each situation. This is what Naava’s artificial intelligence is for.

AI guides the system’s functions remotely in real time based on the data transmitted by the sensors. This ensures that the smart green wall has optimal efficiency, with almost zero effort from the client. The sensor technology and AI don’t just react to changes but they can also predict them. This way the plants are guaranteed to have even more stable living conditions, which in turn makes for an even more efficient smart green wall that isn’t fazed by changes.

With continuous and individual monitoring, we make sure of the smart green wall’s wellbeing and efficiency on the client’s behalf.

The frame production team also works closely in cooperation with product development and our team of IT experts to further develop the automation, functions and design of Naava to fit the needs of the client.

After finishing with the frame modules and sub-assembly, the Naava is put together. Once the frame is ready, it continues its journey towards plant production.

Naava plants are made to last

The tropical plants arrive to the New Jersey factory from our contractor. After their arrival, they spend a few days in our humid and warm greenhouse. In homey living conditions, the plants get a chance to recover from stress caused by traveling. Once they have rested, the plants are planted into Naava’s very own, soilless growth medium.

Our own mixture of growth medium is a better choice than soil, as it offers the microbes of the plant roots a more extensive growth surface, thus activating the growth of good microbes. This in turn leads to the microbes breaking down impurities more effectively.

Moreover, the growth medium allows air to flow through easier. This way, it creates noticeably pure and fresh air quickly and efficiently together with microbes, unlike the plants of conventional green walls.

When Naava’s plants are replanted, not only is the growth medium changed but the plants also go through a process where they are refined into biological air purifiers.

Only the plant specialists at Naava know exactly how to nurture and handle the plants so that they become as efficient as possible. However, at the same time they take care of the wellbeing of the plants in order to make sure they are alive and well to do their job effectively once they are at the client’s premises.

The arrangement of plants is a carefully thought out process

The plants are placed in frames fresh from the replanting station. When arranging the plants onto the wall, the specialists go for soft and natural shapes, just like they appear in the nature. Moreover, the needs of the plants are taken into consideration. For instance, vines get by better at the top of Naava rather than at the bottom, due to lower levels of humidity.

Greenhouse trains Naava to perfection

After the arrangement of plants is finished, Naava continues its journey into the greenhouse. It is in the warmth of the greenhouse that Naava gets to spend a three week acclimation phase. During this phase, the plants get to unwind from the stress caused by the replanting process in the humid, warm air of the greenhouse.

The greenhouse is like a training hall for the plants.

The plants are gradually trained to their full potential in the greenhouse in order to make them purify and humidify air as efficiently as possible once they continue on their journey to the client. Thus, the greenhouse could be described as a training hall of sorts for the plants.

Once Naava leaves the greenhouse, its condition is carefully checked. Not a single smart green wall goes to the client directly from the greenhouse, but they are first taken to a prepping area, where the wellbeing of each plant is individually checked.

The finishing touch

During the prepping, Naava has to tick all the boxes of standards before it is delivered to the client. This way we make sure that the plants are on the top of their game and that all parts of the smart green wall are working as they should.

After the delivery, Naava gets to take some time off to settle down in its new home during another stress relief period, where the artificial intelligence lowers the air circulation to a minimum so that the plant roots can take a breather. After adapting to its new environment for a bit, Naava is ready to work.

However, Naava’s journey doesn’t end once it leaves the factory. Thanks to maintenance by the Naava Service team, the smart green wall remains just as stunning and active as the day it leaves the factory for years to come.

Setting up shop in New York

Naava has recently branched out to the Big Apple to bring the fresh Nordic air into New York offices, too. As the smart green wall is home to dozens of real, living plants, it couldn’t be shipped across the pond from the Nordics. So, Naava’s brand new New Jersey factory was set up.

The Naava crew of the spacious NJ factory has adopted and revised the manufacturing techniques developed at Naava’s original factory in Finland, but also added a few things of their own to the mix.

After a quick visit to the Finnish factory, two of the main improvements our NY team members Jon Magee and Bill Seavey decided to do at the new facility were better work stations and better organization of inventory.

“Even though we only have five people working in the operations side of the US, we have quite a large facility. The size enables us ample room for spreading out tasks in multiple workstations, storing goods in an organized fashion, and having flexibility down the road,” said Jon.

“We are continuously looking for ways to improve our operations. Recently, we have been trying to iron out the logistics/coordination side of things to ensure our promises to customers are met as promised.”

Are you interested in a Naava of your own?

Leave us a message and let's bring the outdoors indoors.